KARADENIZ TECHNICAL TEST CENTER

KTTM is not only a laboratory specialized in safety footwear testing but also a benchmark of trust and quality.

With our international accreditation and scientific expertise, we enable brands reach and surpass global safety standards.

We guarantee trust in every step, impartiality in every test, and scientific accuracy in every report.

QUALITY CONTROL

KTTM founded in 2018 in Trabzon Teknokent, performs comprehensive tests and analysis for safety footwear and its components in accordance with TS EN ISO 20344 and related international standards to determine the product compliance with the quality standards precisely.

Our rigorous and scientific efforts since establishment led us to receive our first accreditation in 2022 according to the standard TS EN ISO/IEC 17025 – General Requirements for the Competence of Testing and Calibration Laboratories. The fact that 70% of the proficiency tests we participate in are of international origin is the strongest indicator of our global reliability.

Today, KTTM continues to be a reference point for quality and trust, providing standard-compliant tests and analysis services not only for safety footwear but also for casual shoes, leather, textiles, protective equipment, and polymer-based materials.

TEST PROCESS

Our expert and experienced teams carry out all tests meticulously in 7 stages:

TEST REQUEST FORM

The applicant completes the "Test Request Form" in full. The form includes details such as the type of test requested, product features, related standards for test methods (e.g., TS EN ISO 20344), contact information, and the number of samples to be submitted.

EVALUATION PROCESS

Once the form reaches us, our technical team evaluates the application. The applicability of the test, required sample quantity, conformity to requested standards, and completeness of information in the form are reviewed. Additional information or corrections may be requested if necessary.

SAMPLE SUBMISSION

After approval, the applicant must deliver the required number of samples to our laboratory. Samples should be properly packaged and shipped under appropriate conditions

WAIVER STATEMENT FORM (IF REQUIRED)

If fewer samples than specified are submitted, the applicant is required to sign a “Waiver Statement Form” which grants approval for the test to be conducted under specified conditions.

PAYMENT AND CONFIRMATION

Upon sample acceptance and test confirmation, payment details and bank information are shared with the applicant. Once payment is received and approved by our finance department, the test/analysis work plan is initiated automatically.

TESTING AND ANALYSIS OF SAMPLES

Samples are tested by our expert laboratory staff according to the relevant standards. The testing period may vary depending on the test method applied.

TEST RESULTS

Data are verified, and the final report is delivered to the applicant in digital or printed form. The report includes the tests performed, methods used, and results obtained in details.

Footwear Impact Resistance Test

Color Fastness to Friction Test

Cold Resistance Test

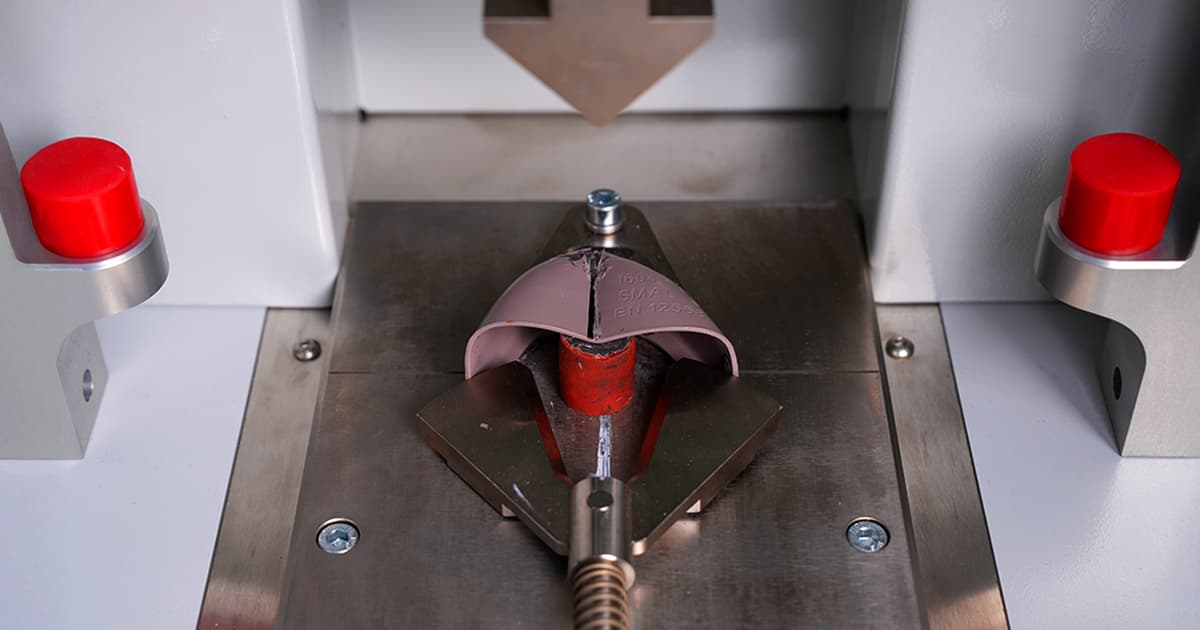

Footwear Impact Resistance Test

Color Fastness to Friction Test

Cold Resistance Test

Footwear Impact Resistance Test

Color Fastness to Friction Test

Cold Resistance Test

Footwear Impact Resistance Test

Color Fastness to Friction Test

Cold Resistance Test

Footwear Impact Resistance Test

Color Fastness to Friction Test

Cold Resistance Test

Footwear Impact Resistance Test

Color Fastness to Friction Test

Cold Resistance Test

Tension Test and Elongation Percentage Determination

Tear Resistance Determination (Constant Rate of Tear Methods)

Flex Resistance Determination

Sliding Resistance Determination (NaLS+Gliserin)

Tension Test and Elongation Percentage Determination

Tear Resistance Determination (Constant Rate of Tear Methods)

Flex Resistance Determination

Sliding Resistance Determination (NaLS+Gliserin)

Tension Test and Elongation Percentage Determination

Tear Resistance Determination (Constant Rate of Tear Methods)

Flex Resistance Determination

Sliding Resistance Determination (NaLS+Gliserin)

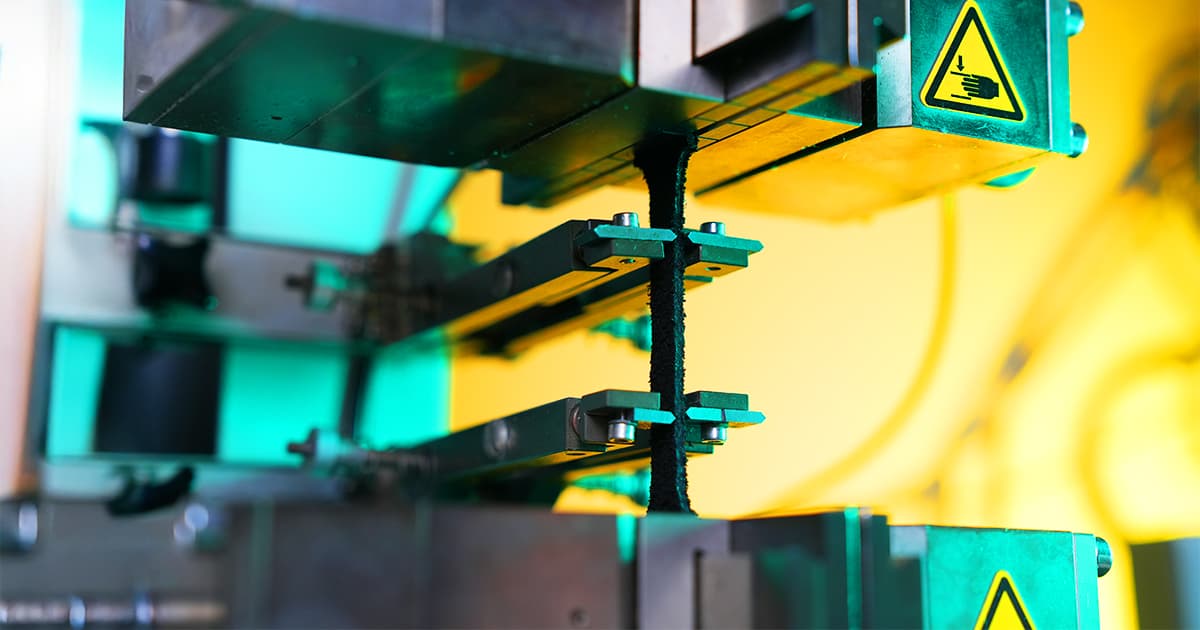

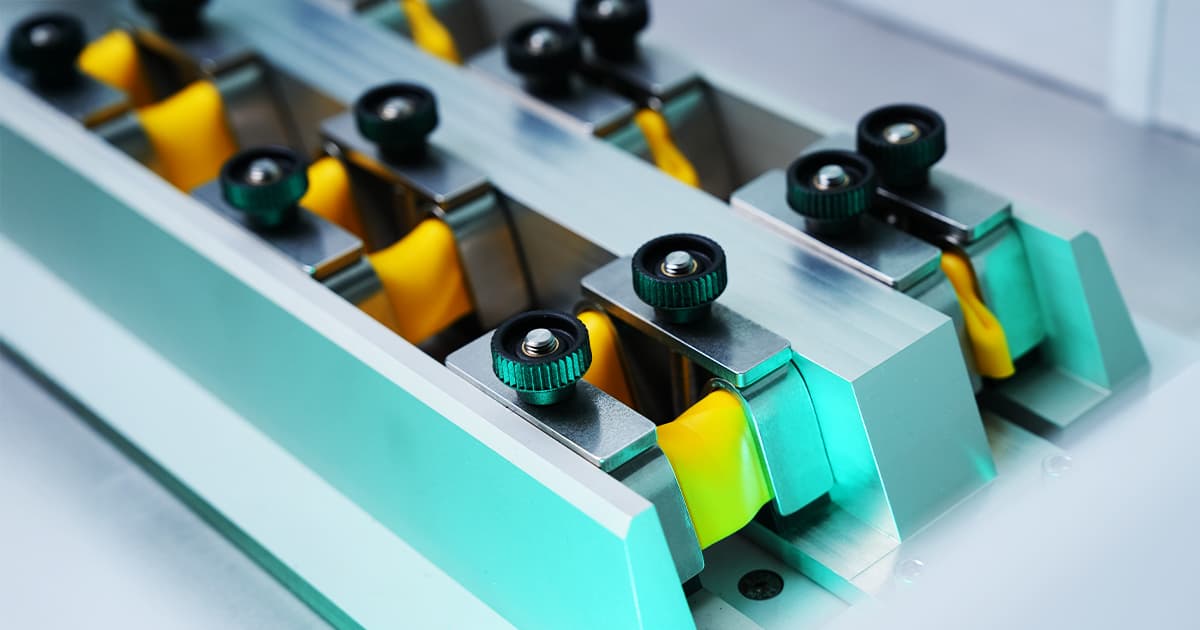

OUR TECHNOLOGY

We as KTTM continue all our testing processes in our state of the art laboratories.Our high-precision equipment and advanced automation systems provide maximum accuracy, reliability, and repeatability for each test.

GALLERY

GALLERY

GALLERY

GALLERY

GALLERY

GALLERY

GALLERY

GALLERY

GALLERY

GALLERY

GALLERY

GALLERY